|

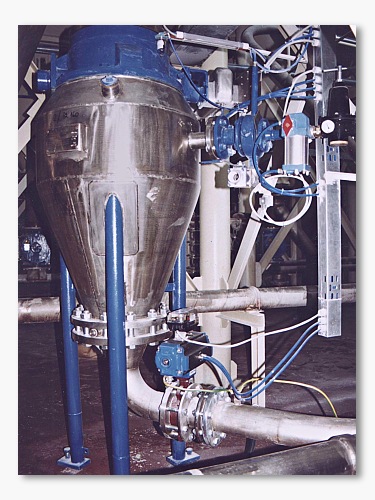

Pneumatic conveying projects

Pneumatic conveying is generally used for purpose of powdery material conveying, when transporting by hydraulic or mechanical devices for various reasons, can not be used.

Conventional reasons speaking for usage of pneumatic conveying instead of mechanical transport are as follows:

- Lower degradation of transported substance by mechanical friction and crushing during mechanical transport

- Suitable for when transport distance is too long and super-elevation of transport way is too big

- Less dustiness and joint leakage at mechanical components

- Lower mechanical wear of machinery and equipment

- Lower repair and maintenance demands (Higher reliability of machines equipment)

BCS Engineering, A.S. is able to ensure the following activities and services:

- Specification of suitable type of pneumatic conveying, alternatively special kind of conveying

- Technical assistance during the reconstruction of the improperly designed, existing pneumatic conveying

- Design documentation

- Delivery and assembly of complete equipment

- Modification of intercommunication between feeder and existing control system

Pneumatic conveying is divided in dilute phase and dense phase conveying to ratio - transported substance/air quantity necessary for conveying.

|